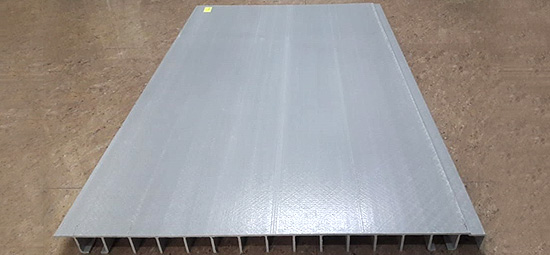

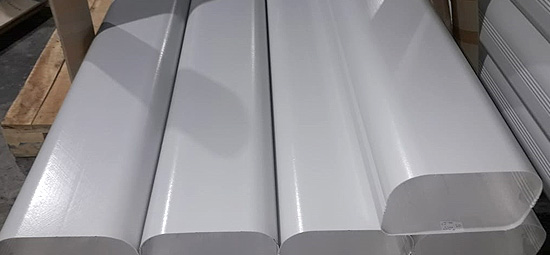

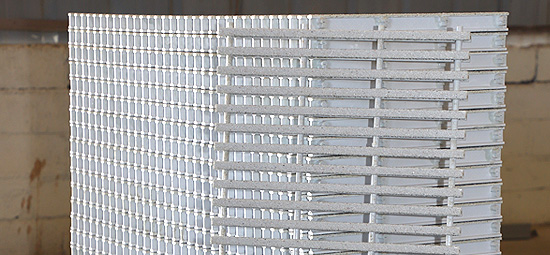

Pultrusion is a continuous moulding process whereby reinforcing fibres are saturated with a liquid polymer resin and then carefully formed and pulled through a heated die to form a part. Pultrusion results in straight constant cross section parts of virtually any shippable length.

Pultrusion is a continuous moulding process whereby reinforcing fibres are saturated with a liquid polymer resin and then carefully formed and pulled through a heated die to form a part. Pultrusion results in straight constant cross section parts of virtually any shippable length.

RIL-VCD is currently having 40+ Pultrusion lines with a manufacturing capacity of 10000+ MTPA of Pultruded Profiles to cater to the emerging needs of FRP Pultruded Profiles across the globe.